Engine Coming

Geared Coaxial Stirling Engine Precision Piston Metal Engine Model Kit Science and Education Physics Experiment Toy - M20-TZ-01

Geared Coaxial Stirling Engine Precision Piston Metal Engine Model Kit Science and Education Physics Experiment Toy - M20-TZ-01

Couldn't load pickup availability

Geared Coaxial Stirling Engine Precision piston metal Engine Model Kit Science and Education Physics Experiment Model Toy - M20-TZ-01

Specifications:

Product number: M20-TZ-01

Size: 178X128X138 (MM)

Product weight: 1.35KG

Total weight: 1.5kg (with packaging)

Heating tube inner diameter: 20MM

Piston stroke: 15mm

Power piston diameter: 20MM

Flywheel diameter: 78MM

Belt pulley diameter: 20MM

Total number of bearings: 8 (pieces)

Base material: phyllostachys pubescens

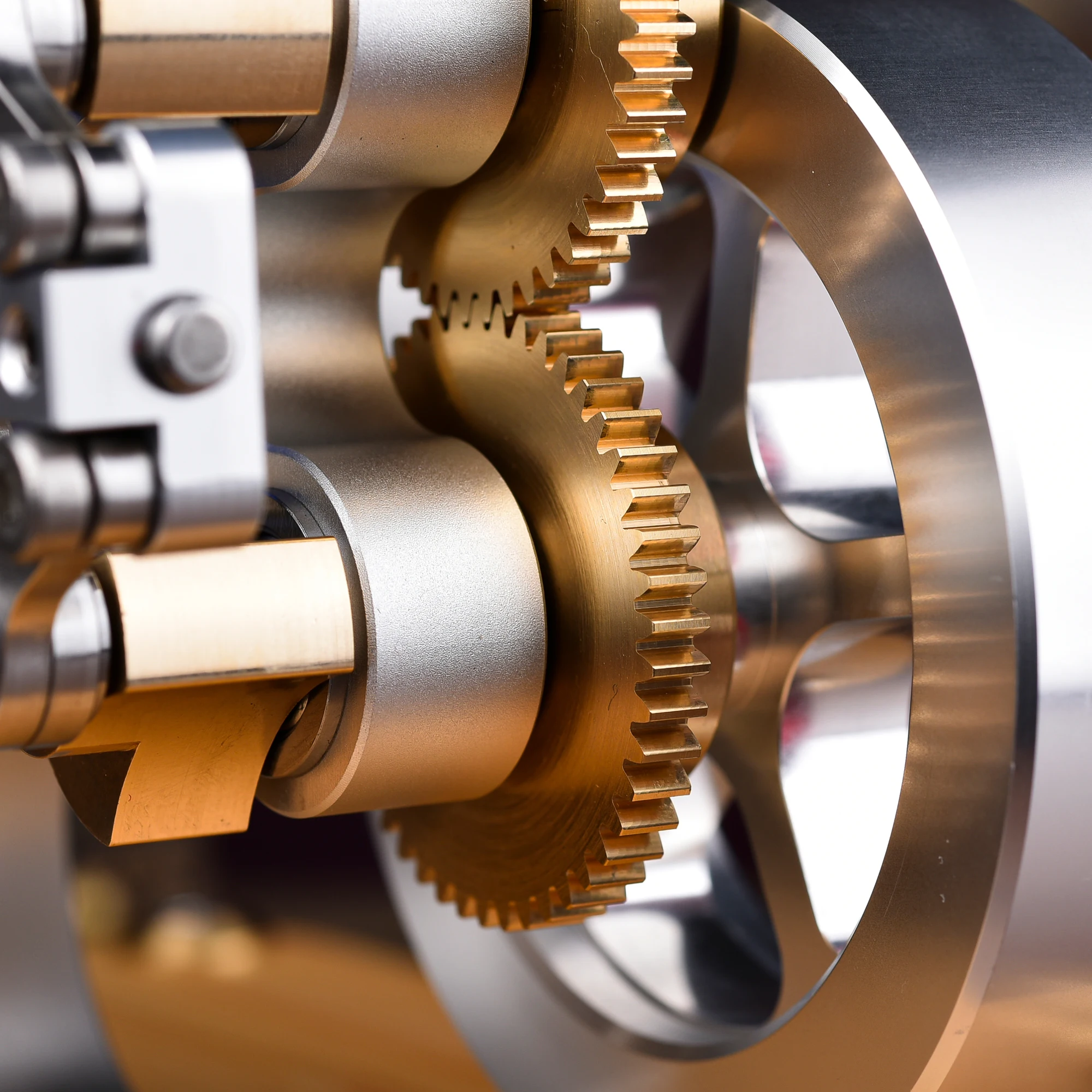

Gear material: brass

Material of crankshaft wheel: brass

Heating tube material: 304 stainless steel

Material of crankshaft connecting rod: 304 stainless steel

Air exchange piston material: 6061 aluminum alloy

Power cylinder liner material: bearing steel

Material of power piston sleeve: bearing steel

Heat exchange connecting rod material: stainless steel

Support material: 6061 aluminum alloy

Wheel material: 6061 aluminum alloy

Cylinder liner shell material: 6061 aluminum alloy

Feature:

This is the first time we have used a coaxial structure for Stirling engines since 2012, which may be one of the few structures in China so far.

This M20-TZ-01 uses a 20MM power cylinder combined with a 20MM 304 stainless steel heating tube to fully integrate two sets of systems into one cylinder block. The two sets of brass gears are in the same position with the crankshaft wheel for movement. In order to maximize the service life of the cylinder and piston, we choose bearing steel GCR15 as the raw material for the cylinder and piston sleeves. After CNC lathe processing, it undergoes quenching treatment to increase the hardness to 58-62HRC. After grinding treatment, the accuracy can reach around plus or minus 0.005MM, The piston needs to seal the gas inside the cylinder as much as possible while performing reciprocating motion, which is a key part that reflects Stirling precision. The M20-TZ-01 uses an exaggerated flywheel with a diameter of 78MM and a thickness of 20MM. This makes the weight of a single flywheel of this machine as high as 155 grams, which is 5 times the weight of the M14 series flywheel. A brass gear with a diameter close to 40, a brass crankshaft with a diameter of 25 millimeters, and a cylinder liner with a wall thickness of 2.5 millimeters push the weight of the seemingly compact M20-TZ-01 to 1.4 kilograms.

The redesigned heat exchange piston and cylinder body improve the heat exchange capacity of the machine. After running for 20 minutes, the temperature measured at the position of the machine cylinder body hovers around 100 degrees, while the temperature in the front section of the heating tube reaches around 600 degrees, resulting in a temperature difference of about 500 degrees. This also makes the power output of the machine more continuous.